Case study

Moving heavy equipment in a corrosive environment

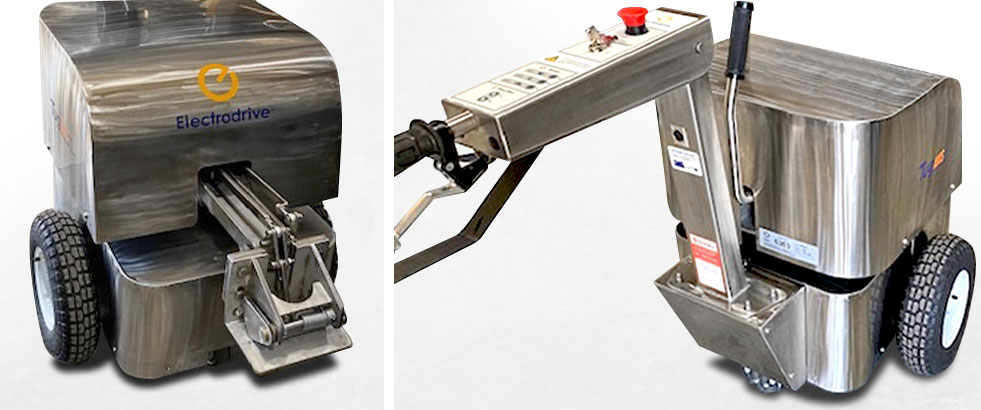

Electrodrive collaborated with a specialist distributor to design-and-build a custom solution for use in the food and beverage industry.

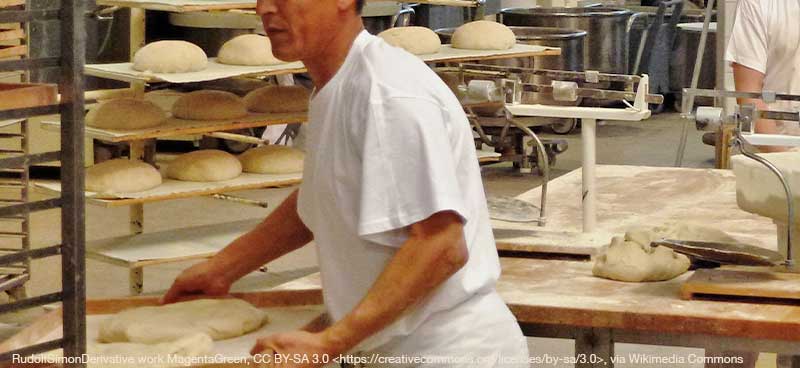

A commercial bakery required a solution to regularly move heavy machinery and equipment from their production line for cleaning.

To manually move a heavy dough mixer and a packaging machine on a regular basis required 2-3 workers. This also increased the employees risk of back and shoulder strain, and could potentially lead to time off work, and extended downtime caused by workplace injuries.

Hygienic stainless steel powered tug

Collaborating with a specialist distributor, Electrodrive designed-and-built a custom solution, a stainless steel corrosion-resistant Tug Axis 2T.

Safely moving commercial bakery machinery

The powered tug enabled a single operator to move up to 2 tonne loads with ease. Its stainless steel body and hitch have been designed to withstand the humid environment within the commercial bakery, and to weather regular cleaning and sanitization.

Tough and durable, the stainless steel tug is corrosion-resistant for hygiene—critical in a food manufacturing environment. It is also ergonomically designed to enable maximum forward visibility for the user, crucial for avoiding collisions with walls/doorways, equipment or staff.

Not only has workplace safety now improved, but efficiency has also increased. What was previously a 2-3 person job, now only requires a single operator to safely manoeuvre manufacturing equipment for cleaning.

Looking for more information?

If you're looking for a similar solution or more information, please contact our product experts.

The powered tug range

Browse our range of powered tugs.